TST: Custom Fabrication

Torn Space TheaterWork performed for Studio NORTH Architecture (Director: Christopher Romano) w/ Michael HooverThis project involved the development of shop drawings and the execution of custom fabrication work to support the build-out and ongoing expansion of Torn Space Theater’s performance and production spaces. The scope focused on translating architectural and theatrical design intent into buildable components through detailed drawings, material testing, and precision fabrication.

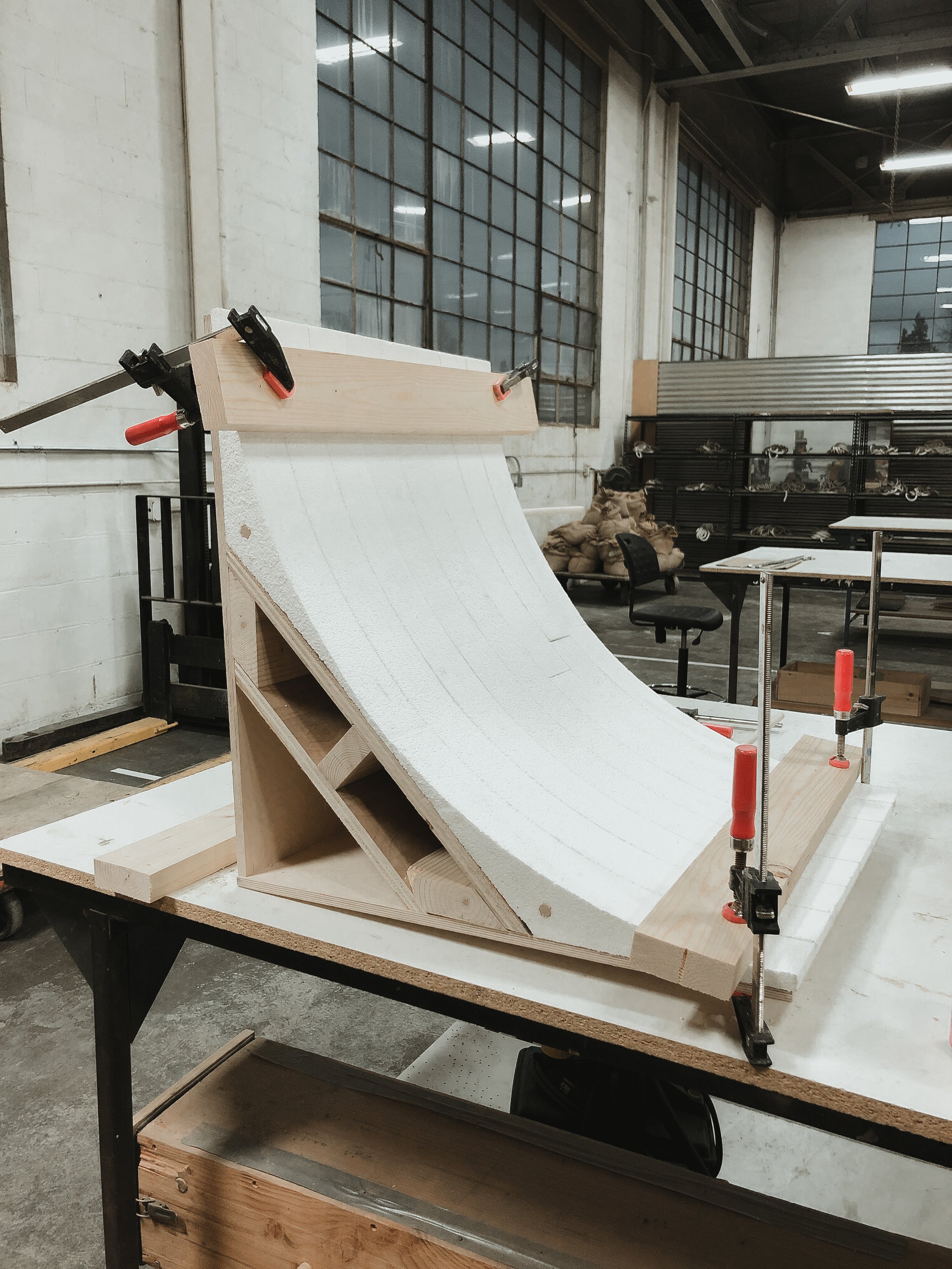

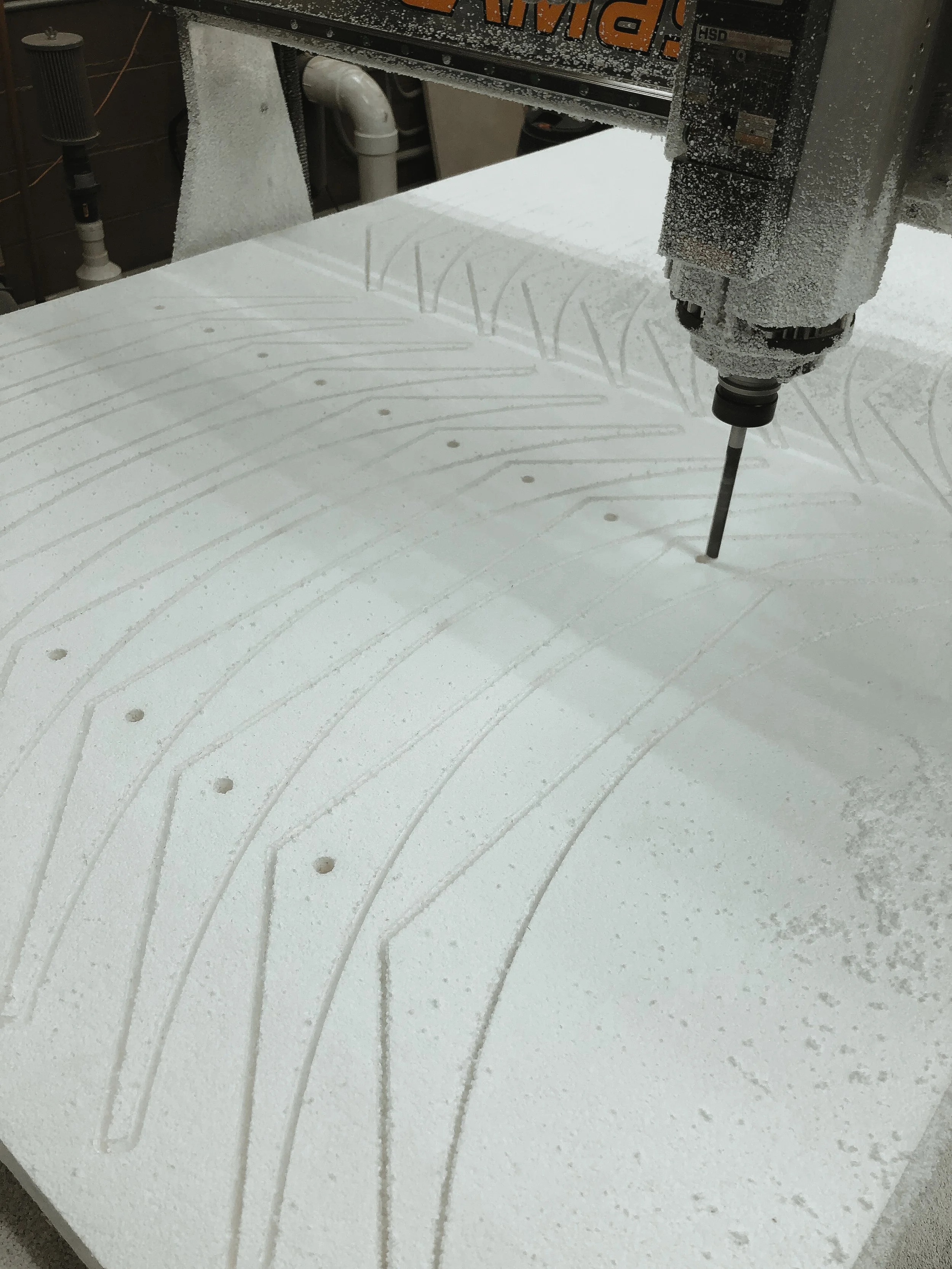

Work included the design and fabrication of custom black-out curtain rail brackets and structural supports to accommodate flexible performance configurations. Custom acrylic window assemblies and window anchoring systems were developed to meet spatial, lighting, and safety requirements while integrating with existing building conditions. Foam inserts were CNC-milled to fit curved wall geometries, providing acoustic and spatial refinement within performance areas.

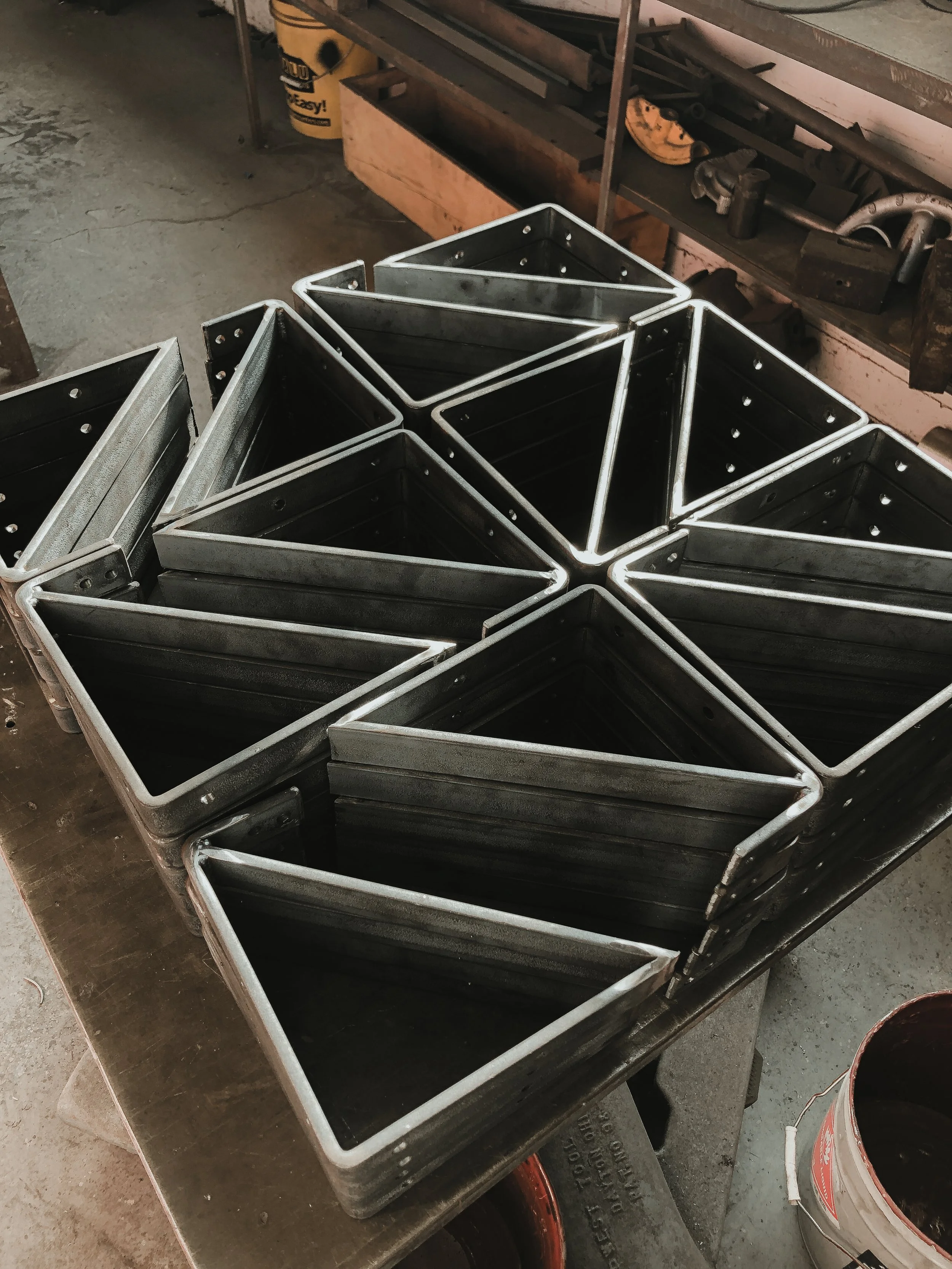

Additional scope included the fabrication of custom handrails, signage, and mounting hardware using a combination of CNC milling, laser cutting, and plasma cutting. Metal components were produced through welding and multi-axis waterjet cutting to achieve tight tolerances and complex geometries not available through off-the-shelf systems.

The project required close coordination between digital modeling, shop drawing production, and physical fabrication, ensuring accuracy between design intent and installed work. This process-driven approach supported rapid iteration, accommodated site-specific constraints, and enabled custom solutions tailored to the theater’s evolving programmatic needs. The work demonstrates an integrated workflow bridging architectural documentation, advanced fabrication technologies, and hands-on construction in a live performance environment.