FT716: Sculpture

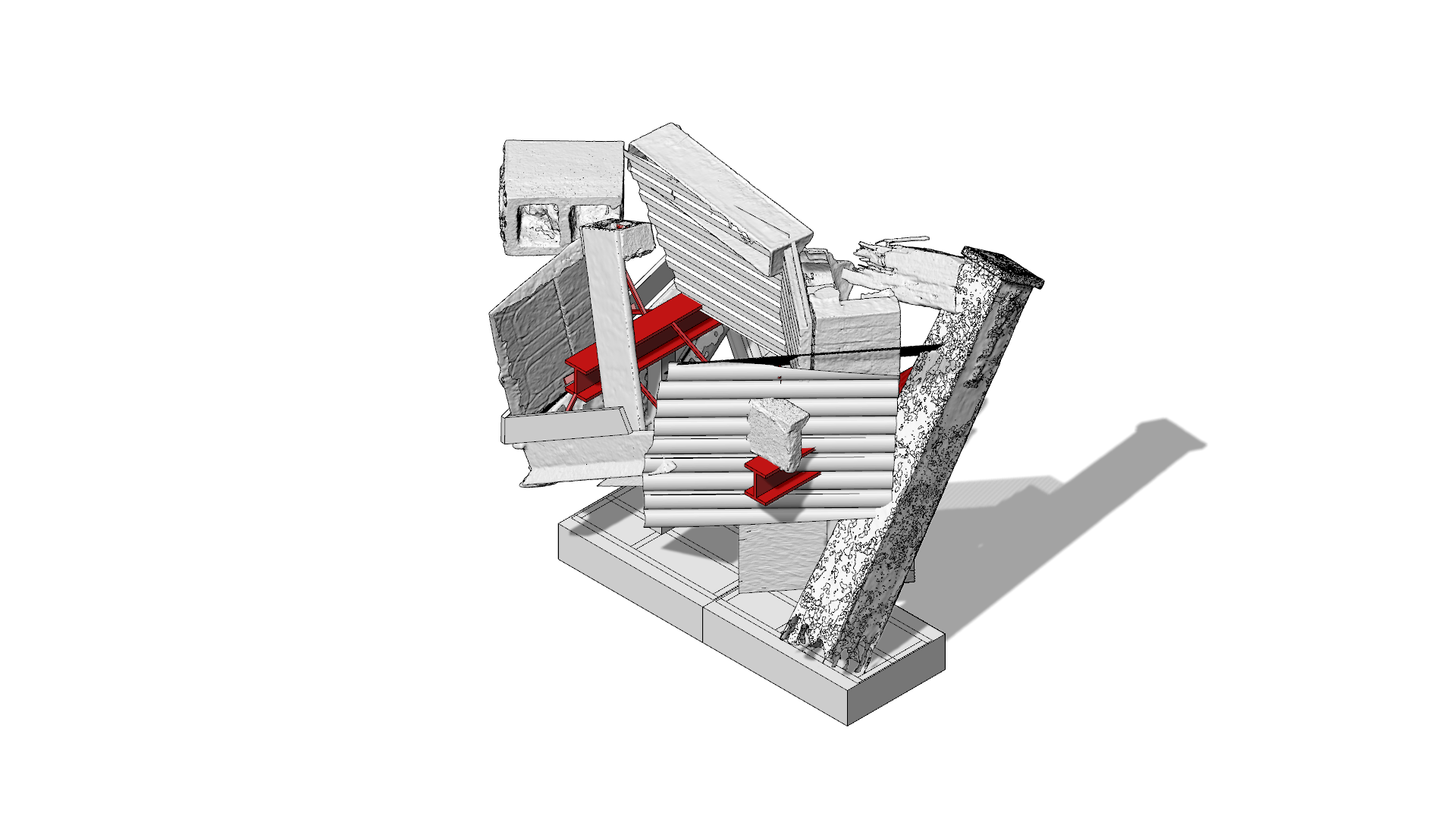

This project documents a collaboration with SASS STUDIO in which advanced 3D scanning and digital modeling were employed to support the organization, coordination, and final production of a large-scale sculptural work composed of reclaimed architectural fragments.

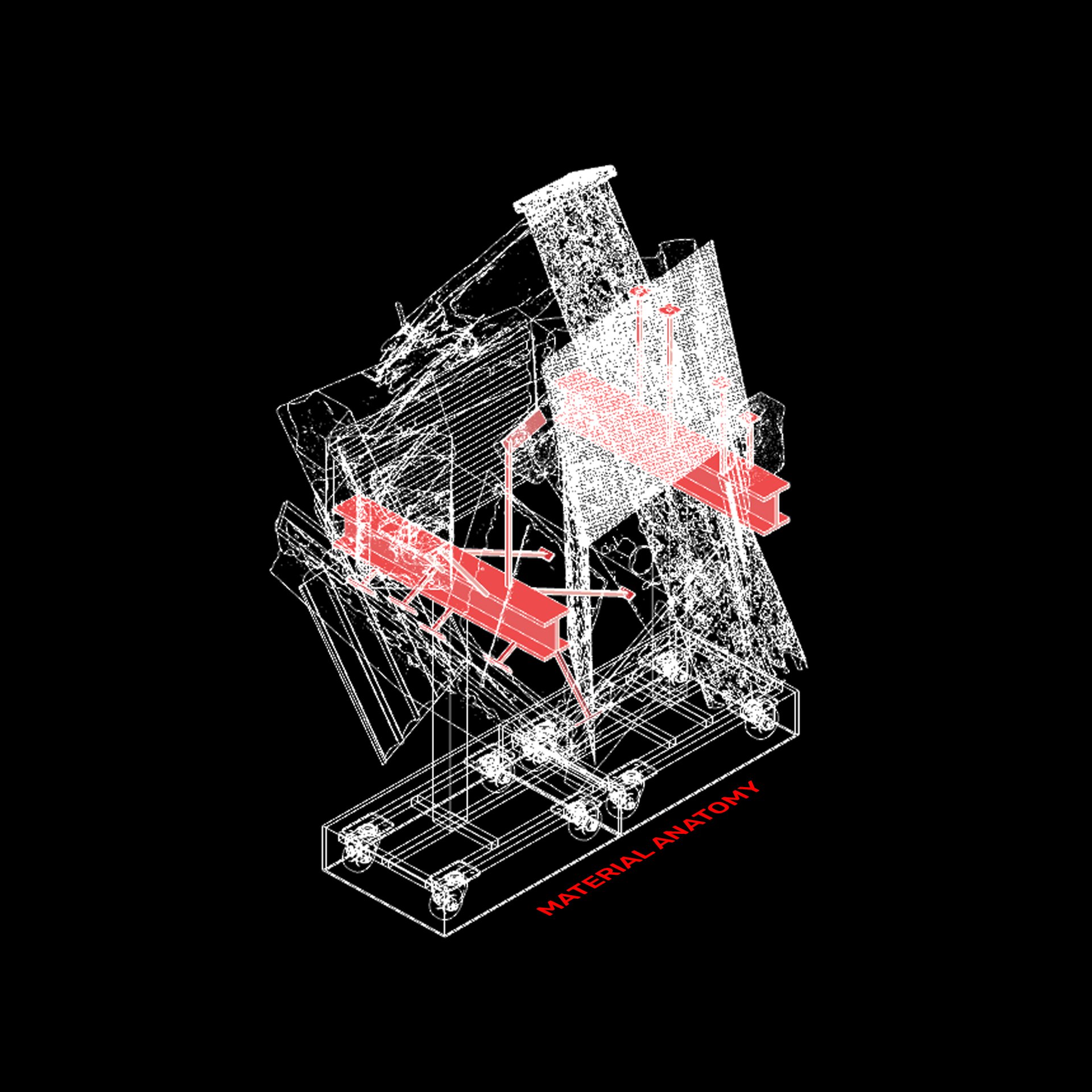

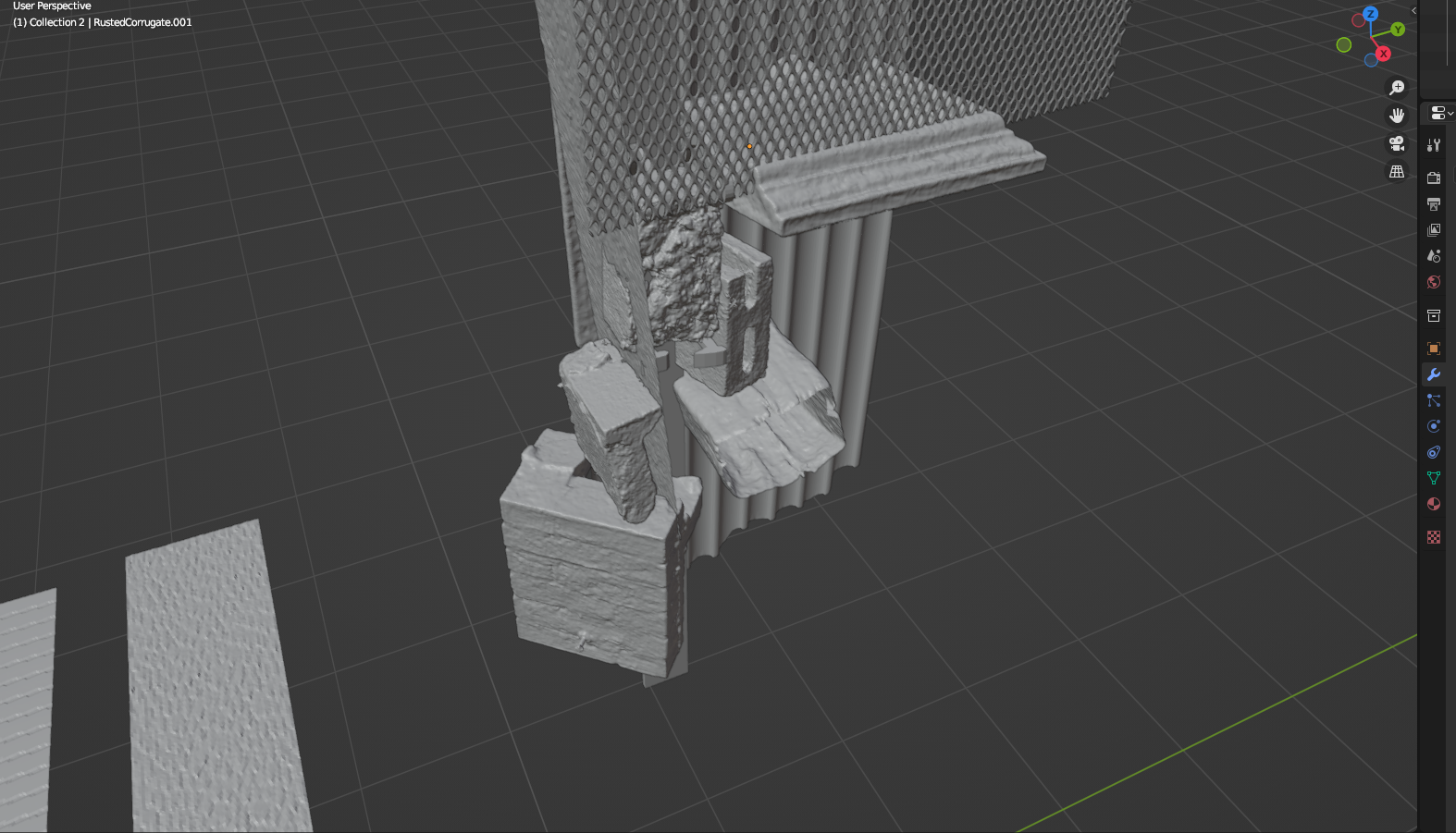

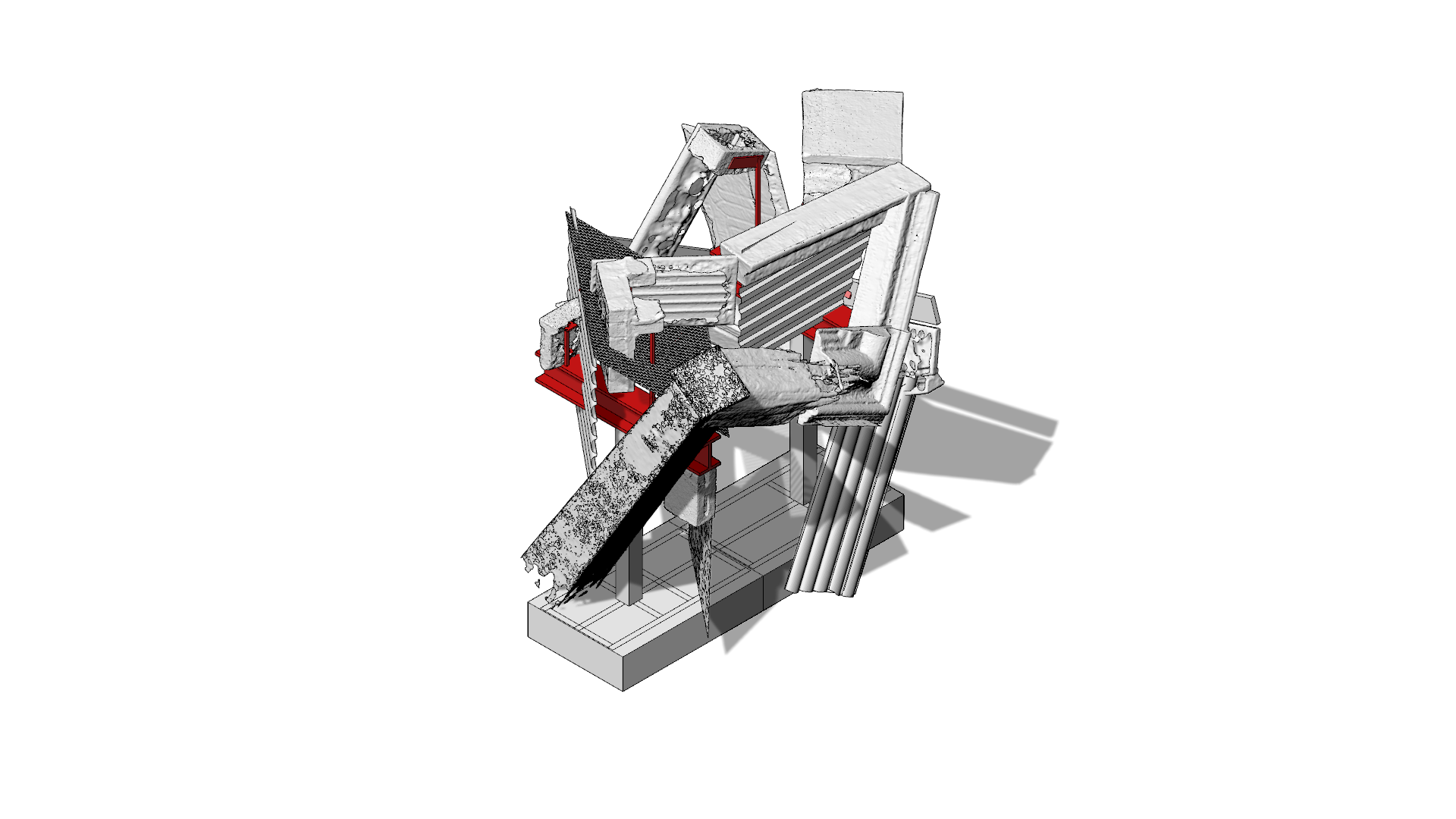

The sculpture itself is an assemblage of salvaged materials—columns, beams, panels, and industrial remnants—layered and balanced to create a dynamic spatial composition. Due to the complexity of the geometry, irregular material conditions, and non-orthogonal connections, traditional documentation methods were insufficient for accurately tracking relationships between parts or supporting fabrication decision-making.

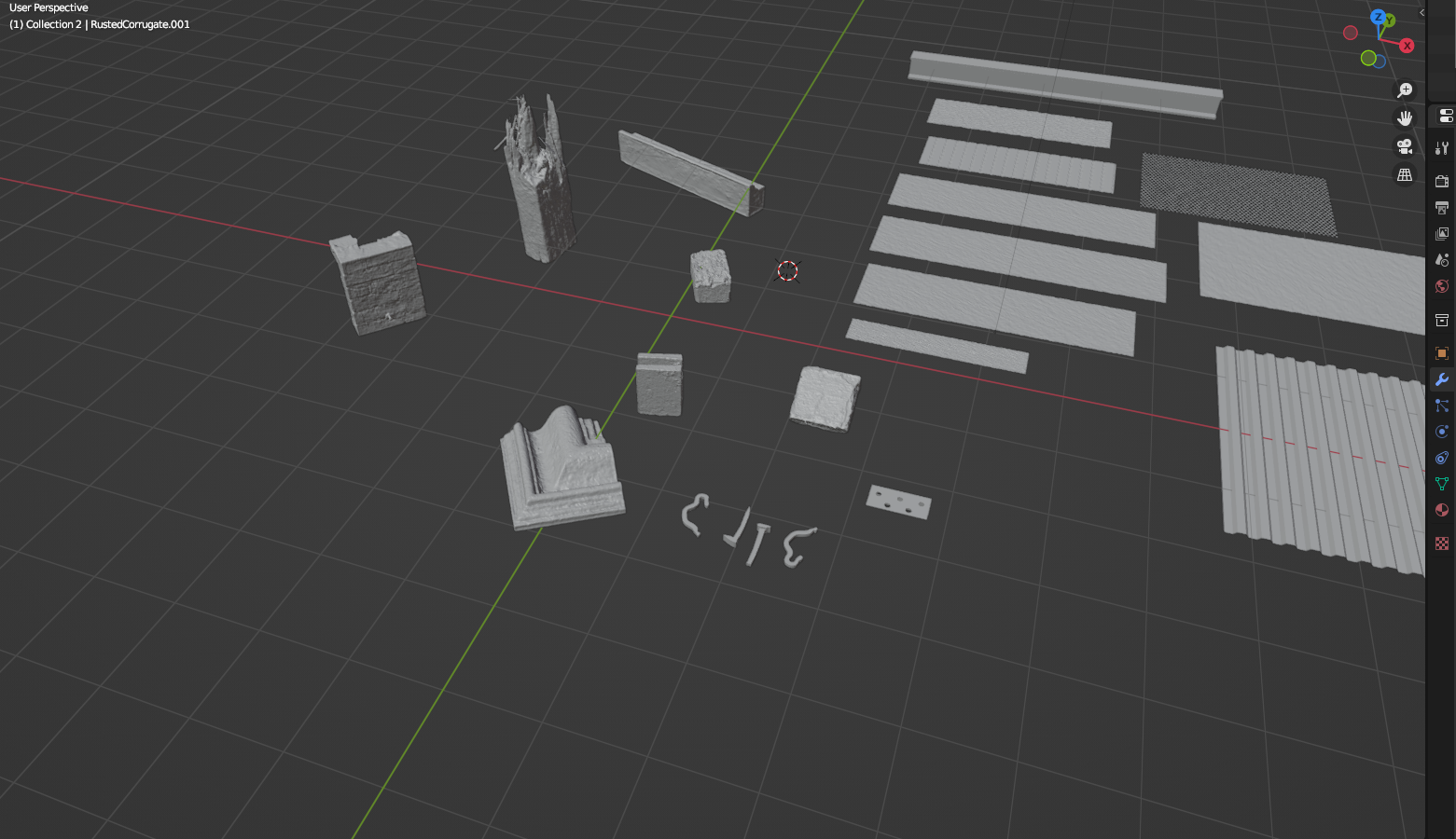

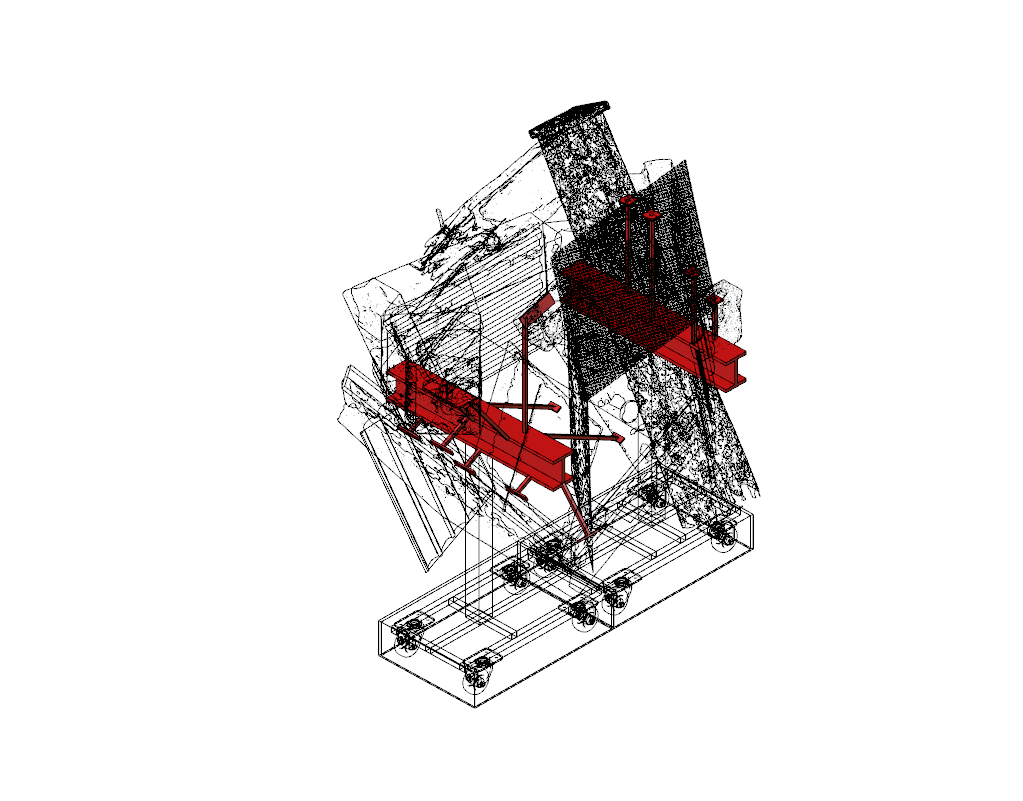

To address this, our team provided high-resolution 3D scanning services, capturing the sculpture in its physical state and translating it into a precise digital twin. The resulting point cloud and derived 3D model allowed the project team to:

Accurately record the geometry and spatial relationships of each component

Test alignments, tolerances, and assembly logic digitally before fabrication

Organize material interfaces and structural connections

Create a shared reference model for coordination between designers, fabricators, and installers

The digital model became a central tool in moving the sculpture from an intuitive, hands-on assemblage toward a resolved and buildable final condition. By bridging physical craft and digital precision, the workflow ensured fidelity to the original artistic intent while enabling clarity, efficiency, and confidence in production.

This project demonstrates how 3D scanning can function as an organizational and design intelligence tool, not just as documentation—supporting complex sculptural practices where material irregularity, improvisation, and spatial density are central to the work.